Troubleshooting High Power Laser Cutting: Common Problems and Effective Solutions

With inimitable advantages similar to thick metal sheet ability, presto cutting speed, and capability to cut thicker plates, high-power fiber laser cutting has been extensively honored by the request. still, because high-power fiber laser technology is still in the original stage of popularization, some operators aren’t veritably professed in high-power fiber laser chops.

The high-power fiber laser machine technician of Golden Laser has added up a series of results to high-power fiber laser cutting problems through long-term testing and exploration, for reference by all associates in the assiduity.

Firstly, the following reasons should be checked first

If the cutting effect is set up to be poor.

1. All lenses in the laser head are clean and free of pollution;

2. The water temperature of the water tank is normal, and the laser has no condensation;

3. The chastity of the laser cutting gas is excellent, the gas path is smooth, and there’s no gas leakage.

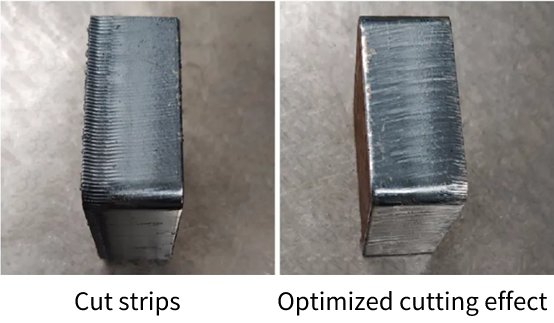

Question 1 Cut strips

Possible Causes

1. The snoot selection is incorrect and the snoot is too large;

2. The air pressure setting is incorrect, and the air pressure is set too high, performing in stripes after overheating;

3. The laser cutting speed is wrong, too slow or too presto will beget full overheating.

Solution:

1. To replace the nozzle, replace the nozzle with a small periphery. For illustration, for a 16 mm carbon sword bright face slice, you can choose high-speed nozzle D1.4 mm; for a 20 mm carbon sword bright face, you can choose high-speed contact nozzle D1.6 mm;

2. Reduce the air pressure and ameliorate the slicing quality of the end face;

3. Acclimate the laser cutting speed. Only when the power matches the slicing speed duly can the effect shown on the right as shown below be achieved.

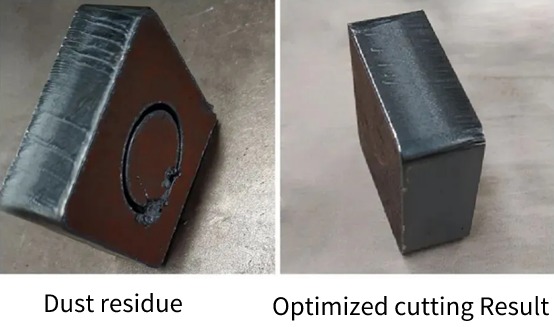

Problem 2 There’s dust residue at the bottom

Possible Causes:

1. The nozzle selection is too small, and the laser focus doesn’t match;

2. The air pressure is too low or too high, and the laser cutting speed is too fast;

3. The material of the metal sheet is poor, the quality of the board isn’t good, and it’s delicate to remove the dust residue with a small nozzle.

Solution:

1. Replace the large-periphery nozzle and acclimate the focus to a suitable position;

2. Increase or drop the air pressure until the air inflow is applicable;

3. Choose a good metal plate.

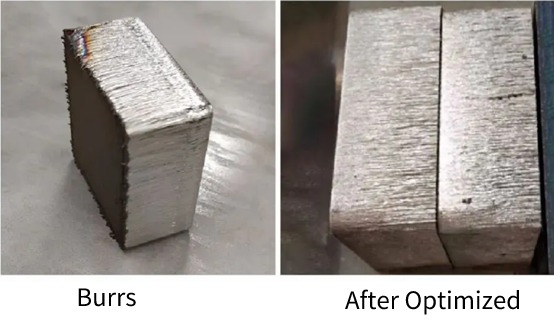

Problem 3 There are burrs at the bottom

Possible Causes:

1. The nozzle periphery is too small to meet the processing conditions;

2. still, you should increase the negative defocus and acclimate the proper position If the negative defocus doesn’t match.

3. The air pressure is too small, performing in burrs on the bottom, which can not be completely cut.

Solution:

1. Choose a large- periphery nozzle to increase the air inflow;

2. Increase the negative defocus to make the laser beam section reach the nethermost position;

3. adding the air pressure can reduce the bottom burrs.

If you have any questions or good suggestions, welcome to contact us for further discussion.