2018 Laser Processing Equipment Manufacturing Industry Analysis

1.Laser processing equipment manufacturing industry development status

Laser is one of the four major inventions in the 20th century that are famous for atomic energy, semiconductors, and computers. Due to its good monochromaticity, directionality, and high energy density, lasers have become a representative of advanced manufacturing technologies and an important means of upgrading and transforming traditional industries. In the industrial field, the most important application of laser technology is laser processing.

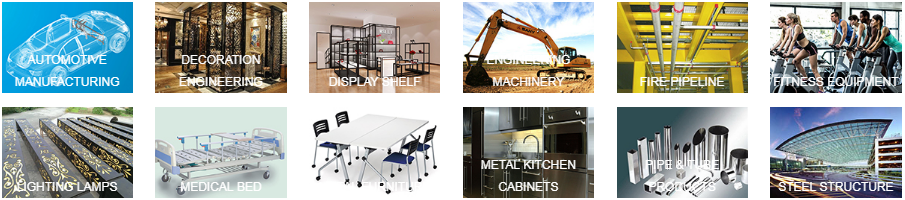

Laser processing is a processing technology that uses laser beams to cut, weld, surface-treat, punch, and micro-process materials. It has been widely used in automobile, electronics, aerospace, metallurgy, and machinery manufacturing and other important national economic sectors. Increased product quality, labor productivity, automation, and reduced material consumption play an important role.

Laser processing equipment mainly includes laser marking machines, laser cutting machines, laser welding machines and other equipment. The main function of the laser marking machine is to etch patterns, trademarks and texts on the surface of various materials such as metal, leather and plastic. Laser cutting machine can cut metal and other materials, has more applications in sheet metal processing, and gradually replace the traditional processing methods. Laser welding machines mainly weld thin-walled materials and precision parts such as connector welding and power battery top welding.

2.Future of laser processing equipment manufacturing industry

First of all, the application fields of China’s laser processing equipment industry will be expanded from the traditional industries of electronics, automobiles, steel, petroleum, shipbuilding, and aviation to the six high-tech fields of information, materials, biology, energy, space, and oceans. The demand in the field will also bring about a new round of growth in China’s laser processing equipment industry. Secondly, with the strong support of the nation, provinces, and cities, our laser technology has reached a high level and scale regardless of the R&D team, R&D investment, and R&D level. The R&D lasers cover various wavelengths required for current laser manufacturing. In the time domain, some of the technical levels have reached the international advanced level. As the industry further develops, related technical capabilities will continue to increase. Thirdly, the concept of intelligence is a hot spot in the development of China’s new economy. Domestic laser companies actively participate in major national intelligent manufacturing projects, and intelligence has thus become one of the future development trends in the laser processing equipment manufacturing industry. “Laser+” automation applications It will provide the most advantageous solution for industrial 4.0 flexible manufacturing. Finally, the urgent need for the upgrading of China’s manufacturing industry will boost China’s laser industry for another decade. In the next five years, the laser processing equipment manufacturing industry will maintain an average annual growth rate of 15%. Domestic companies need to continuously carry out scientific and technological innovations, industrial upgrading, and expand the R&D team to become the mainstay in the new development.