- Home

- News

- Cnc Professional Fiber Laser Pipe Cutting Machine P3080A For Metal Tube Materials Processing Industry

Cnc Professional Fiber Laser Pipe Cutting Machine P3080A For Metal Tube Materials Processing Industry

With the rapid growth of the production and consumption of stainless steel pipes in International Market, the tube processing technology has also developed rapidly. In particular, the advent of laser pipe cutting machines has brought unprecedented qualitative leap to the pipe processing. As a professional laser cutting machine, pipe laser cutting machine is mainly used for laser cutting of metal pipes.

As we all know, any new processing technology can be recognized by the general public, and it is rapidly developed. It is bound to have features that cannot be achieved by traditional techniques. What advantages does the laser pipe cutting machine have?

There are two main points:

1. Flexibly

How can a laser cutting machine be called flexible? It is almost how you want to cut it.

It can cut any shape that hasbeen programmed on a stainless steel pipe, and the laser can be perfectly cut in any direction. The shape to be machined can be flexibly and quickly

changed by computer programming. The high flexibility of the laser cutting machine provides

powerful technical support for more and more personalized processing, thereby reducing the

number of molds used.

2. Accuracy.

Compared to traditional processing equipment such as flame cutting, plasma cutting, and water cutting,

the precision of laser cutting of metal plates is much higher. At the same time, as mentioned above,

different materials may undergo slight expansion and contraction during processing. Laser cutting tube

machine can be flexibly adjusted according to these deformations, which is also not reachable

by many conventional processes.

At present, the laser cutting technology abroad is very mature, and the “Made in China”

curve overtaking has also become more and more popular in the international market.

For example, the laser pipe cutting machine equipment of VTOP Laser has occupied a place in the global market. This is inseparable from

the obvious advantages of the equipment itself.

Golden VTOP Pipe Laser cutting machine P2060A performance characteristics

1.Laser pipe cutting machine centralized operation, flexible processing, automatic loading and unloading,

convenient and quick installation.

2.The laser pipe cutting machine uses a precision rack double drive mode, which is easy to maintain

and maintain, and is basically free of maintenance.

3.The laser pipe cutting machine adopts imported special pipe cutting software and has a core technology

for efficient cutting, which is a fundamental guarantee for effectively saving materials and improving

cutting efficiency.

Pipe Laser Cutting Samples

Based on the above advantages,VTOP laser cutting machine is widely used in fitness equipment,office furniture, kitchen cabinets and other

industries of circular tube, square tube, rectangular tube and profiled tubes and other profile processing,

in addition to a large number of major industrial areas in the country to introduce applications outside ,

VTOP laser is still vigorously expanding the international market, speed up the upgrade, is committed to

providing global users with better products, more efficient services and a more comprehensive overall

solution for the laser industry

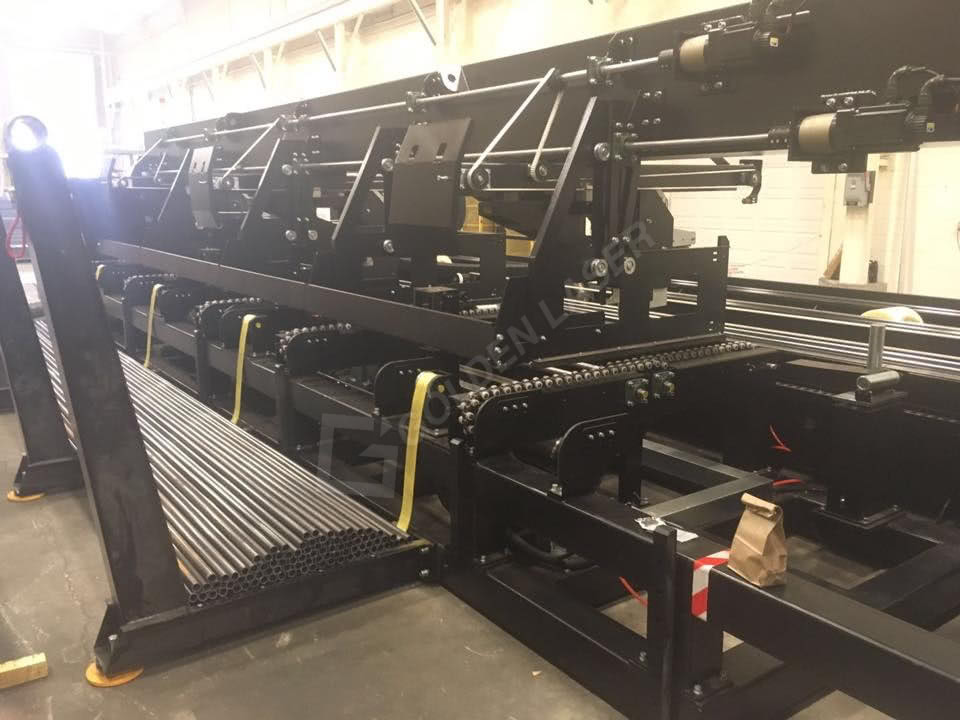

Automatic Bundle Loader Tube/Pipe/Profile Fiber Laser Cutting Machine P3080A 3000W

Installed in the US

The machine can cut 8m length tube,tube diameter from 20mm to 300mm.

Automatic bundle loader of the model P3080A

Our engineer is debugging this device in the customer’s factory