Laser Comprehensive Solution for Outdoor Stent Tent

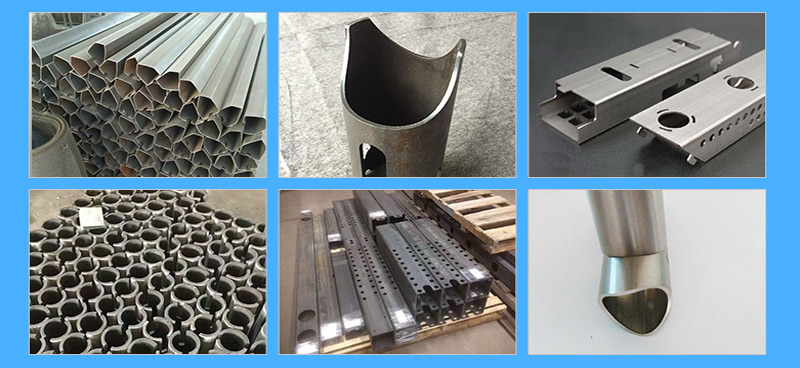

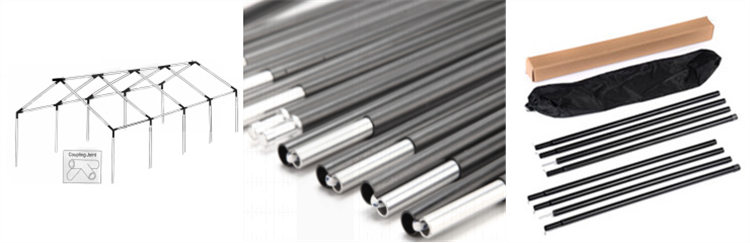

Stent tents are adopting frame forms, it consists of metal stent, canvas and tarpaulin. This kind of tent is good for sound insulation, and with good rigidity, strong stability, heat preservation, rapid molding and recovery. The stents are the supporting of the tent, it was usually made from glass steel and aluminum alloy, the length of the stent is from 25cm to 45cm, and the supporting pole hole’s diameter is 7mm to 12mm.

Recently, we got a customer who was for outdoor tent production, visited our factory. From the customer, we knew that stent tent production needs many procedures, such as pipe sawing, lathe processing, holes punch and drill, pipe TIG welding etc.

Firstly, it needs sawing machine for pipe cut off, the cutting should in accordance with the drawing and it needs to remove the sharp burrs by manual.

Secondly, it goes with lathe processing for chamfer cutting and inner or outer holes burrs removing.

Thirdly, after cutting off, it needs the punching and drilling machine for holes punch and drill etc.

Fourthly, the pipe needed to be welded together, and the plant needs paste label to mark all the pipe in order.

After all these procedures the factory get the stent. But it needs many sets of sawing, punching, drilling machines, but also needs too many workers.

In order to upgrade the production efficiency and adapt to modernized production requirements, the customer did many market research, finally they contacted golden laser and want to introduce GOLDEN-VTOP LASER welding machine.

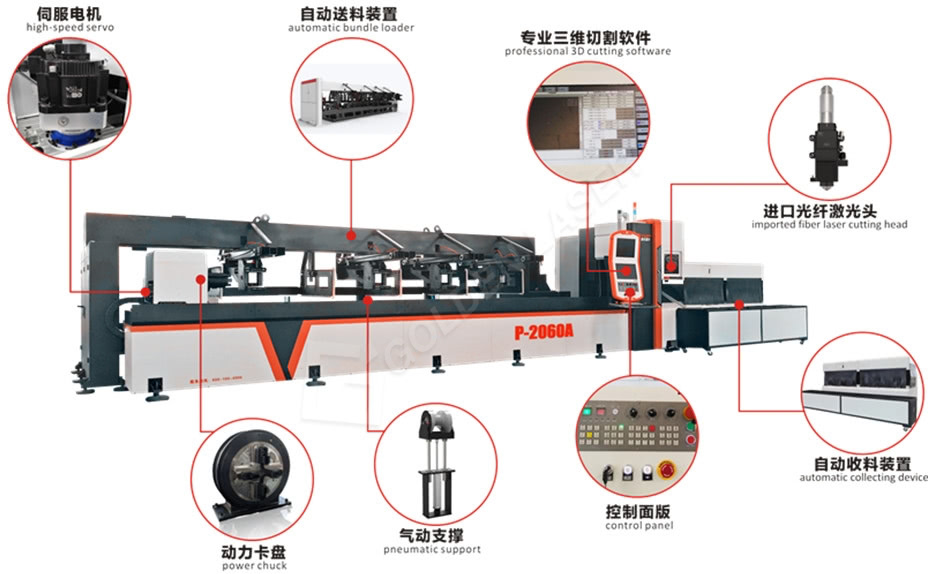

Golden Vtop laser pipe laser cutting machine is suitable for all kinds of tube or pipe cutting, it can process pipe or tube length of 6m, 8m and 12m, and the diameter of 10-300mm. Now it has been successfully applied in industries such as pipe processing, fitness equipment, steel furniture, car chassis, showcase and shelve, construction etc. Golden laser pipe laser cutting machine is euqiped with automatic bundle loader system, so it does not needs worker to load pipes.

And it has the following advantages:

1. Save labor and floor space

Because pipe laser cutting machine can reduce 3-4 punch machines, 1-2 drilling machines, 1-2 abrasive saw machines. Thus it saves the floor space of 1-2 workshops and human costs about 7 persons. Reduce processing step and save time.

Pipe laser cutting machine can achieve automatic marking, CNC cutting and forming by one time, it suits for all kinds of pipe and cutting requirements (cut through, beveling, slotting, drilling, cutting flowers), and the cutting end surface is sooth without deburring and black-edged.

2. Saving materials

The pipe laser cutter can automatically calculating the layout and cutting ways, almost no waste materials. No direct connection between the cutting head and the pipe wall, so the cutting end surface is smooth and without black-edged, no deformation of the finished products and nearly no loss.

3. High accuracy

Golden laser pipe laser cutter can automatically seek edge and do correction, even with long-term continuous cutting, it still ensures the accuracy and the consistency of finished product. The chuck can be automatically adjusted and installed, with auto unloading, it eliminates the artificial impact on finished product.