7 Difference Between Fiber laser cutting machine and Plasma cutting machine

The 7 Difference point between fiber laser cutting machine and Plasma cutting machine.

Let’s compare with them and select the right metal cutting machine according to your production demand. Below is a simple list of the mainly difference between fiber laser cutting and Plasma cutting.

| Item | PLASMA | FIBER LASER |

| Equipment cost | Low | High |

| Cutting result | Poor perpendicularity:reach 10 degreeCutting slot width: around 3mmheavy adhering slagcutting edge roughheat affects greatlynot accuracy enoughcutting design limited | Poor perpendicularity:within 1 degreeCutting slot width: within 0.3mmno adhering slagcutting edge smoothheat affects smallhigh accuracyno limited on cutting design |

| Thickness range | Thick plate | Thin plate、Medium plate |

| Using cost | power consumption、Touch the mouth loss | quick-wear part、Gas、power consumption |

| processing efficiency | Low | High |

| Feasibility | rough processing、thick metal、Low productivity | precise processing、thin and medium metal、High productivity |

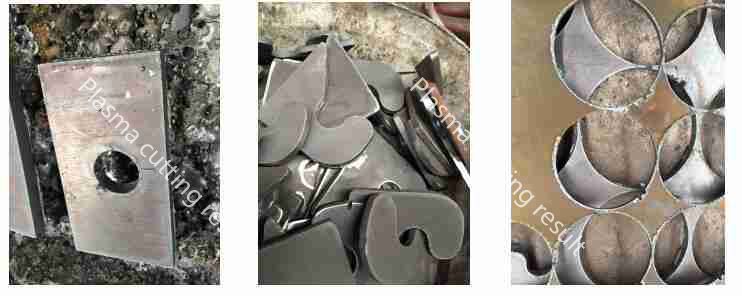

From Above picture, you will find the Six DISADVANTAGE of PLASMA CUTTING :

1、The cutting heat affects greatly;

2、Poor perpendicular degree on cutting edge, slope effect;

3、Scrape easily on edge;

4、small pattern impossible;

5、not accuracy;

6、Cutting slot width;

The Six ADVANTAGE OF LASER CUTTING:

1、small cutting heat affects ;

2、good perpendicular degree on cutting edge,;

3、no adhering slag,good consistency ;

4、valid for hige precise design, small hole is valid;

5、accuracy within 0.1mm;

6、Cutting slot thin;

As fiber laser cuttting ability on thick metal materials increase a lots, which reduce the cutting cost on metalworking industry.